Problems and Solutions in the AAC Brick Factory

The production formula has remained unchanged throughout the entire production process, so the root cause of the existing issue does not lie in the formula itself. Instead, it mainly stems from the slurry's high viscosity and low diffusivity—two critical characteristics that directly influence the slurry's fluidity and spreading performance during application. This problem becomes even more prominent when using finer-sized slurry, as the smaller particle size tends to cause particle aggregation. Such aggregation further reduces the slurry's diffusivity, thereby exacerbating the overall issue. Additionally, poor lime quality also contributes significantly to this problem; it is important to emphasize that this is not merely an issue related to aluminum paste, but rather a comprehensive problem involving multiple raw material components.

Beyond the slurry and lime-related factors, the quality of the sand used in production is another important cause of the problem. Specifically, if the sand selected for the production process is excessively fine in particle size and contains a high mud content, the big hole problem will also occur during production. The excessively fine sand particles, combined with impurities such as mud, disrupt the normal bonding and combination of raw materials in the system. This disruption leads to the formation of pores during the curing process, which ultimately manifests as the big hole issue in the final product.

In the Chinese production context, another key factor to consider is the water absorption capacity of fly ash. Compared with ordinary sand commonly used in production, the fly ash utilized in China has an excessively strong water absorption capacity. When fly ash is added to the production system, it absorbs a large amount of water from the slurry. This excessive water absorption affects the slurry's fluidity and uniformity, as the reduced water content in the slurry impairs its ability to spread and bond evenly. This, in turn, further leads to more serious big hole problems in the final product, making fly ash a notable contributing factor in the Chinese production scenario.

To effectively address and resolve the above-mentioned problems, the following targeted measures should be implemented in the production process:

1. Adjust the slurry diffusivity appropriately. Based on the actual production conditions and on-site requirements, optimize the slurry's formula parameters in a targeted manner. The primary goal of this adjustment is to reduce the slurry's viscosity while improving its diffusivity, ensuring that the slurry maintains good fluidity and a uniform spreading effect during application, which helps to avoid pore formation.

2. Strictly inspect the sand's particle size and mud content before it is put into use. Implement a rigorous screening process for the sand to ensure that its particle size meets the specified production standards. Control the particle size within a reasonable and optimal range, and effectively reduce the mud content in the sand. This step is crucial to avoid impurities from affecting the bonding of raw materials and the overall product quality.

3. Adjust the lime particle size to make it finer. Finer lime particles have a larger specific surface area, which enables them to mix more thoroughly and evenly with other raw materials in the system. This improved mixing enhances the uniformity of the entire raw material mixture, thereby alleviating the adverse effects caused by poor lime quality and reducing the occurrence of the big hole problem.

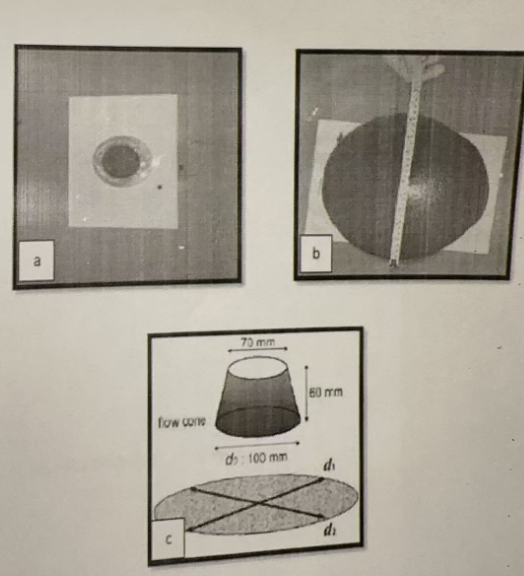

4. Conduct strict slurry testing in accordance with the standard shown in my photo. Establish a regular slurry testing mechanism to timely detect any changes in the slurry's performance, such as fluctuations in viscosity or diffusivity. By identifying these changes in advance, production parameters can be adjusted promptly to ensure the slurry maintains stable performance, thereby preventing the occurrence of the big hole problem.