Mirror Chrome Aluminium Paste

Brand jie han

Product origin shan dong

Delivery time 1week

Supply capacity 100ton per year

Mirror Chrome Aluminium Paste

advantage : when use for plastic coating, it is smooth Surface like metallic effect

when use for inks, based on the silk screen printing, the reverse side gets the mirror effect

spc :10um solid 10%

Download

Technical Data Sheet

Product name/type

MirrorAL- Mirror Chrome Aluminium Paste

Product introduction

Mirror AL mirror aluminum pigment is one dimensional nano-structure pigment made from nano-level thin film obtained by PVD method, using water as medium deciduation and combines the modern powder preparative technique; The mirror colored aluminum pigment is firmly coated by special pigment and surface modifying additives after being activated, surface modified, and chemical and physical coating technologies.

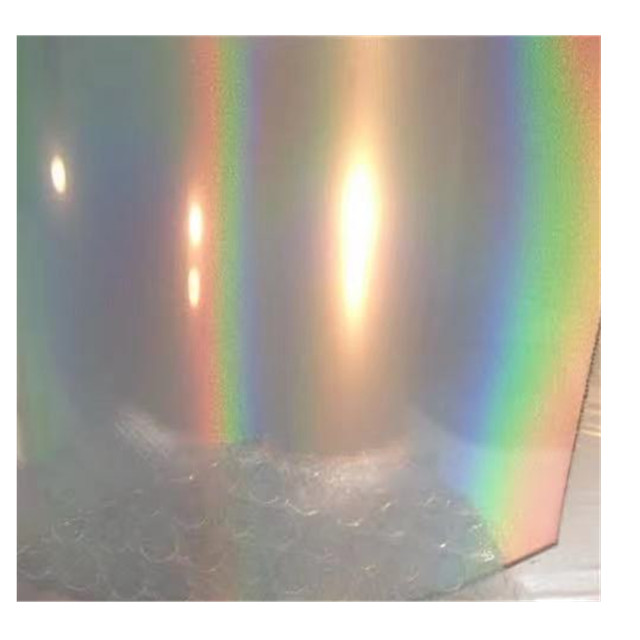

The surface of the pigment thin film made by PVD method is similar to the mirror, which has high reflection and strong metallic luster.

The nano-level thickness and the huge radius-thickness ratio contribute to its covering power and the ability to lay in parallel order in the coatings, MirrorAL can get the mirror effect in reverse printing and elegance texture effect in front printing.

Suggested usage

Electroplated level of aluminum pigment is non-float type yet very thin and bright, the aluminum paste is made by vacuum plating and special grinding technique, making the particles smooth, thin and have equal sizes on the nano-level lamelliform structure. The pigment has a huge radius-thickness ratio, strong covering power, great luminance characteristics, a small amount can make a silver plating effect, which is cost effective. This series product is widely used in silkscreen ink, flexography ink, gravure ink and coatings.

vacuum metallized paste

characteristics

we are product from high purity aluminium as raw material , use special atomosphere we call VMP product it. this type aluminium pigment is belong to non leafing. can be reach to Chrome effect .

application :

screen and gravure printing ink refrigerator glass panel , phone logo printing .

Grade | Non volatile Content (%±2) | Particle Size Distribution D50(±2μm) | Solvent | color shade |

V006 | 10 | 6 | EAC/PM/PMA | white brightness |

V008 | 10 | 8 | EAC/PM/PMA | white brightness |

V005 | 10 | 5 | PM/PMA | black bright |

V010 | 10 | 10 | PM/PMA | black bright |

V004 | 10 | 4 | PM/PMA | black bright |

V006 | 10 | 6 | PM/PMA | black bright |

V006 | 10 | 6 | EAC/PM/PMA | white brightness |

V008 | 10 | 8 | EAC/PM/PMA | white brightness |

V005 | 10 | 5 | PM/PMA | black bright |

Product advantages:

The nano-level thin film is obtained by PVD method, which is excellent in covering power.

The advanced deciduation and the after-treatment technologies strengthen the product’s stability.

The products after surface modification will have strong metallic luster, and be better distributed in the application system.

The product’s manufacturing technique adopts the deactivating method, which gives the product a higher stability and better consistency.

Usage

MirrorAL can apply for all kinds of inks and coating systems, which include gravure,flexography and silk screen and flame plating. The substrates can be the paper, plastic, panel,metal, and thin films and so on.

Colored aluminum pigment uses low solid content and high viscosity resin. Specific resin liquid formula can make the pigment evenly arrange on the substrates, suitable ink formula can reduce the erosion to the substrate, and makes it parallel in the ink film.

Stir before using, the suggested percentage of the color aluminum pigment in the ink is 10%-60%, in the coatings is 2-6%,the disperse process should adopt low-cut method, the surface substrate should be clean and smooth, if hardness and abrasive resistance need to be improved, apply a layer of gross oil on the coatings surface.

Storage and packaging

The product should be stored in a cool, dry, ventilated indoor environment; avoid direct contact with eyes, skin and clothing; immediately seal the container after each usage so as to avoid solvent evaporation, serious solvent evaporation may cause irreversible changes to the pigment paste; The product can not be exposed to sparks and flame sources.9106 model products are in 1KG,10KG,20KG non-recyclable packaging. Packaging agreements are subject to discussion.